RHS STEEL SUPPLIES

At Independent Steel, we understand that when you purchase RHS (Rectangular Hollow Section) steel, you need assurance of both quality and service. Our RHS steel is crafted to meet Australian standards, offering superior strength and durability. We provide a variety of sizes and wall thicknesses to suit your specific project needs, ensuring you get the perfect fit every time.

What is Rectangular Hollow Section Steel (RHS)?

Rectangular Hollow Section Steel is a highly versatile and durable material, renowned for its strength and adaptability. It is characterised by its rectangular cross-section and hollow interior, and is widely used in construction and structural applications due to its exceptional strength-to-weight ratio. This design not only provides significant weight savings but also maintains the structural integrity necessary for heavy-duty installations. It is a preferred choice among architects, engineers, and builders for its reliability and performance.

USES AND APPLICATIONS

The hollow section also allows for the integration of other systems, such as ventilation or electrical conduits, adding to its versatility.

It is available in different grades, such as S235JR and S355J2H, which offer varying levels of strength and flexibility, ensuring you can find the right type for your specific needs.

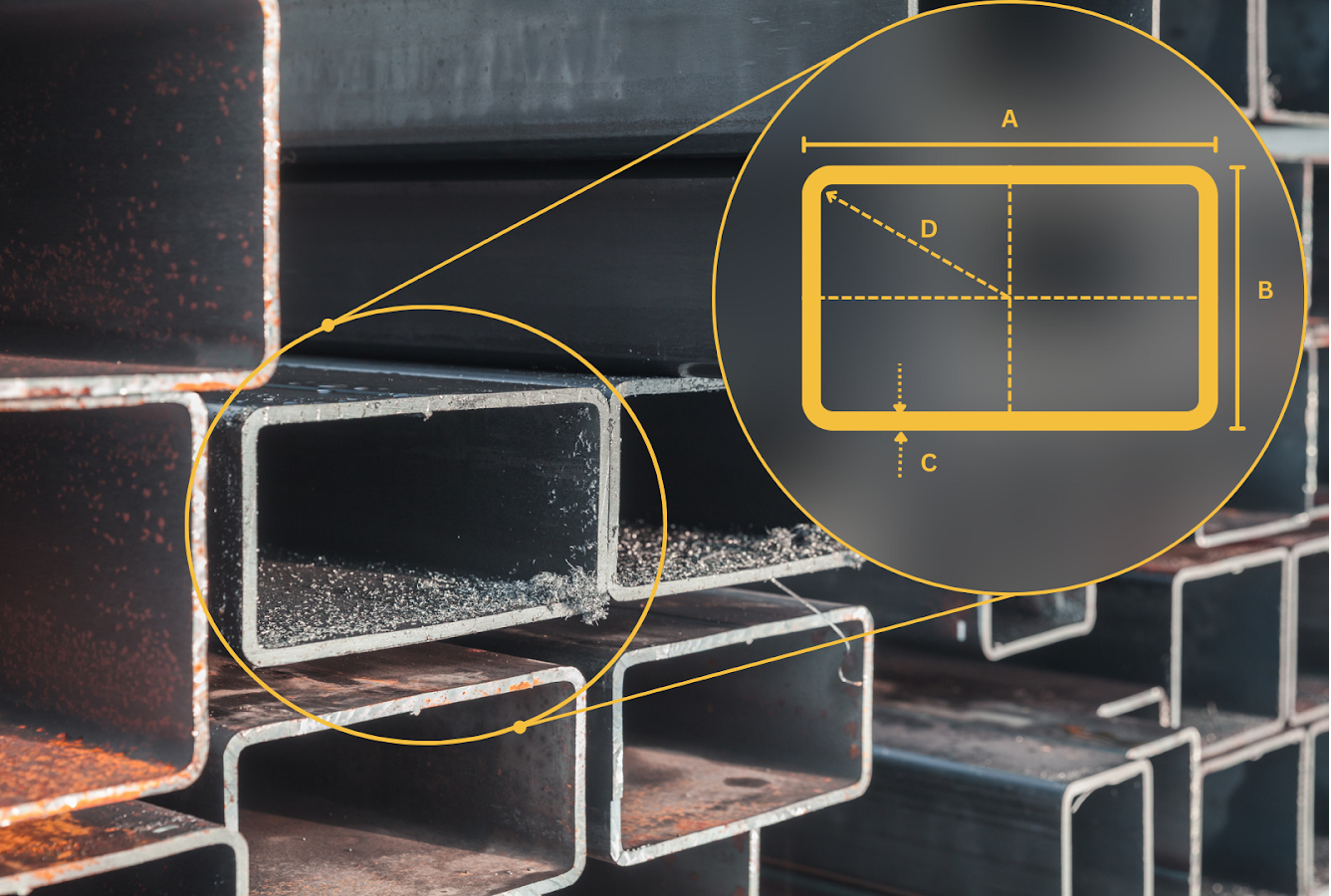

Rectangular Hollow Section (RHS) steel tubes with a close-up view

A= Width, B= Height of the rectangular section, C= Wall thickness.

1. What sizes are available for RHS steel?

It comes in a variety of sizes, ranging from small sections (like 50x25mm) to large ones 200mmx200mm). The size you need will depend on the specific requirements of your project.

2. How does RHS steel compare to other steel sections?

RHS is better for welding and bolting compared to CHS and SHS because it has flatter surfaces. This makes it a preferred choice for many structural applications.

3. What are the advantages of RHS steel over other materials?

It offers several advantages over materials like timber or concrete, including:

- Higher strength-to-weight ratio.

- Greater durability and longevity.

- Better fire resistance.

- Easier to fabricate and install.

4. Are there any specific design considerations when using RHS steel?

When designing with RHS steel, consider:

- The load-bearing requirements of your structure.

- The need for additional coatings to prevent corrosion.

- The type of joints and connections (welded or bolted).

- Compliance with relevant building codes and standards.

5. What grades of RHS steel are available?

Rectangular Hollow Steel is available in various grades, each suited for different applications. Common grades include:

- S235: General structural purposes.

- S275: Medium strength structural applications.

- S355: High strength structural applications.